Why Membrane Switches Are Essential for Creating Compact, Durable Interfaces

Why Membrane Switches Are Essential for Creating Compact, Durable Interfaces

Blog Article

Discovering the Advantages of Membrane Layer Switches for Modern Electronic Devices

The exploration of membrane buttons in contemporary digital tools offers a remarkable point of view on their myriad advantages, specifically in terms of layout versatility, resilience, and cost-effectiveness. As sectors proceed to progress, the role of membrane buttons in improving customer experience and functional efficiency warrants better assessment.

Advantages of Membrane Layer Buttons

Membrane layer buttons are progressively favored in contemporary electronics due to their numerous benefits. One of the main advantages is their compact design, which enables space-efficient integration right into various tools. This slim profile not only conserves space but additionally adds to the general visual appeal of digital items.

Another advantage is their durability. Membrane layer buttons are normally immune to wetness, dirt, and impurities, making them perfect for usage in environments where exposure to harsh conditions is an issue. This resistance expands the life expectancy of the buttons, lowering the demand for frequent substitutes and upkeep.

Moreover, membrane layer switches over offer exceptional tactile feedback, boosting user experience. The responsive reaction is typically created to provide a satisfying experience upon activation, which can boost customer complete satisfaction and efficiency.

In addition, the production process of membrane buttons is economical, permitting reduced production expenses contrasted to standard mechanical buttons. This price makes them ideal for a vast variety of applications, from consumer electronic devices to industrial machinery.

Style Adaptability and Customization

The style flexibility and customization alternatives used by membrane layer changes better enhance their charm in modern electronic devices. These switches can be tailored to fulfill particular visual and useful needs, enabling makers to develop gadgets that align very closely with brand name identity and individual preferences. With numerous choices in terms of colors, forms, and dimensions, membrane switches can effortlessly incorporate right into varied product layouts, whether for consumer electronic devices, industrial applications, or clinical tools.

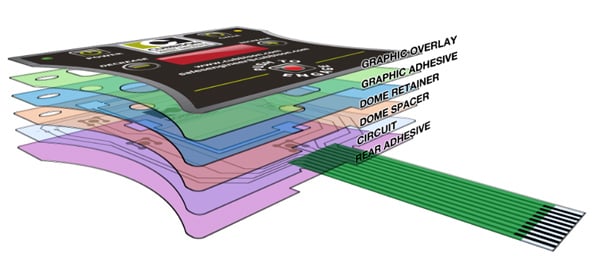

In addition, the capacity to include graphics and icons directly onto the switch surface enhances usability while decreasing the demand for added labeling. This assimilation not just streamlines manufacturing processes yet additionally contributes to a sleeker general look. The design can be further tailored via features such as backlighting, tactile responses, and multi-layer constructions, offering boosted customer interaction.

Sturdiness and Ecological Resistance

Additionally, membrane switches can be engineered to be chemically resistant, making them appropriate for applications in industrial settings where exposure to solvents and cleaning up representatives prevails. The encapsulation of electronic components within the membrane layer structure provides extra security against ecological anxieties, guaranteeing reputable performance also in tough conditions.

In addition to physical durability, membrane switches over display exceptional resistance to UV light, protecting against destruction and staining over time (membrane switch). This particular is particularly beneficial for outside applications, where prolonged exposure to sunlight can endanger various other button types

Inevitably, the toughness and ecological resistance of membrane layer switches over make them an excellent selection for a broad range of modern digital devices, from clinical devices to consumer electronic devices, making sure regular functionality and customer complete satisfaction across various applications.

Cost-Effectiveness in Production

Cost-effectiveness in production is a substantial advantage of membrane layer switches, making them a favored option for manufacturers in different sectors. The production process of membrane layer changes commonly involves fewer materials contrasted to traditional buttons, which decreases raw material costs. This streamlined production process not only conserves money but additionally decreases waste, lining up with contemporary sustainability goals.

Additionally, membrane switches can be produced making use of automated strategies, enabling high-volume result with minimized labor my site expenses. The assimilation of advanced printing modern technologies further enhances performance, making it possible for suppliers to attain elaborate designs and functionalities without incurring significant extra expenses. This scalability makes sure that manufacturing can adjust to changing market needs without endangering top quality or boosting prices.

In addition, the light-weight nature of membrane layer switches adds to set you back financial savings in delivery and handling, along with in the total layout of electronic gadgets. By removing large parts, manufacturers can optimize the general item design, consequently boosting market competition. In general, the cost-effectiveness of membrane changes not only advantages producers economically yet additionally assists in advancement and rapid product development in the vibrant landscape of modern-day electronics.

Applications in Various Industries

Versatility stands apart as a trademark of membrane buttons, enabling them to discover applications throughout a wide variety of industries. In the healthcare industry, these buttons are indispensable to clinical devices, giving user-friendly interfaces for devices like mixture pumps and diagnostic machines. Their resistance to wetness and very easy cleaning make them excellent for settings needing rigorous hygiene requirements.

In the automotive market, membrane buttons contribute to the capability of dashboards and control panels, providing a sleek, modern appearance while guaranteeing resilience against rough conditions. Their light-weight design likewise supports overall vehicle performance.

In addition, commercial equipment utilizes membrane layer switches for operational controls. Their robust nature and customizable functions cater to the particular requirements of varied applications.

Conclusion

To conclude, membrane layer switches over offer substantial benefits for modern-day electronics, including design versatility, toughness, and cost-effectiveness. membrane switch. Their personalized functions and resistance to ecological elements make them appropriate for a large range of applications throughout different sectors. As technical demands continue to evolve, the convenience and efficiency of membrane changes position them as a vital part in improving user experience and driving technology within the competitive landscape of my review here electronic devices

Report this page